Experts in flexible polyethylene packaging

Reliability, innovation, and tailor-made solutions for every need

Priula S.r.l., based in Talamona in the province of Sondrio, about 100 km north of Milan, is a point of reference in the flexible packaging market. Since its foundation in 1982, the company has specialized in the production of high-quality polyethylene bags, pouches, and rolls, widely used for industrial packaging.

Priula’s product range includes bags and pouches with special closures such as minigrip, zipper, and resealable adhesive strips. Initially focused on the local market, the company gradually expanded its reach, becoming a significant player at the national level. Today, a substantial share of production is exported, confirming the quality and reliability of Priula’s products internationally.

Priula products are primarily used in the pharmaceutical and medical sectors, ensuring compliance with the specific requirements of these fields. However, the company also meets the needs of various other industries, including food, textile, clothing, and general manufacturing.

Bag sealing

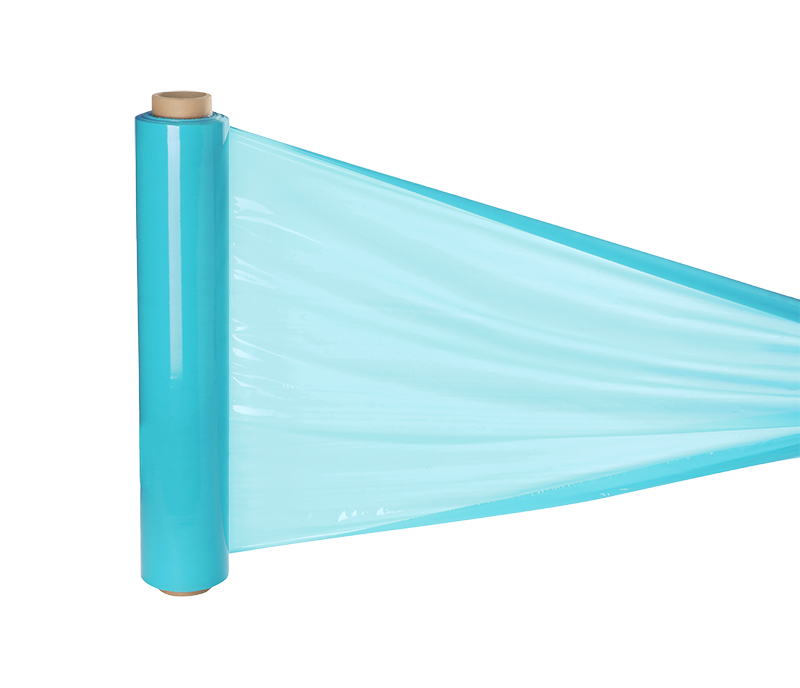

Tubular film for medical use

extrusion film

flexographic printing

material warehouse

Saldatura sacchetti

Tubolare per uso medicale

Estrusione film

Stampa flessografica

Magazzino materiale

immagine

Only certified raw materials: guaranteed quality and safety

The raw material we use, prime virgin polyethylene (low, medium, and high density – LDPE, MDPE, and HDPE), is carefully selected to ensure the highest quality and compliance with safety standards. The polyethylene employed is suitable for food contact, meeting the quality standards.

Upon request, Priula can supply polyethylene that complies with the specific requirements of the European Pharmacopoeia, section 3.1.3 (Polyolefins), demonstrating our commitment to quality and regulatory compliance.

Complete production cycle

The complete production cycle takes place within our Talamona facility and is divided into three main stages:

From the rolls, individual packaging units are produced through cutting and sealing operations.

Strengths that ensure the reliability of our packaging

Guaranteed traceability

production flexibility

Customized packaging

Environmental responsibility

Quality policy

Discover the excellence of Priula’s tailor-made polyethylene packaging.