High-quality packaging for the

Pharma-Medical Sector

Our solutions

features

- Processed material: LDPE (shrinkable upon request), MDPE and HDPE, prime virgin quality, compliant with the European Pharmacopoeia.

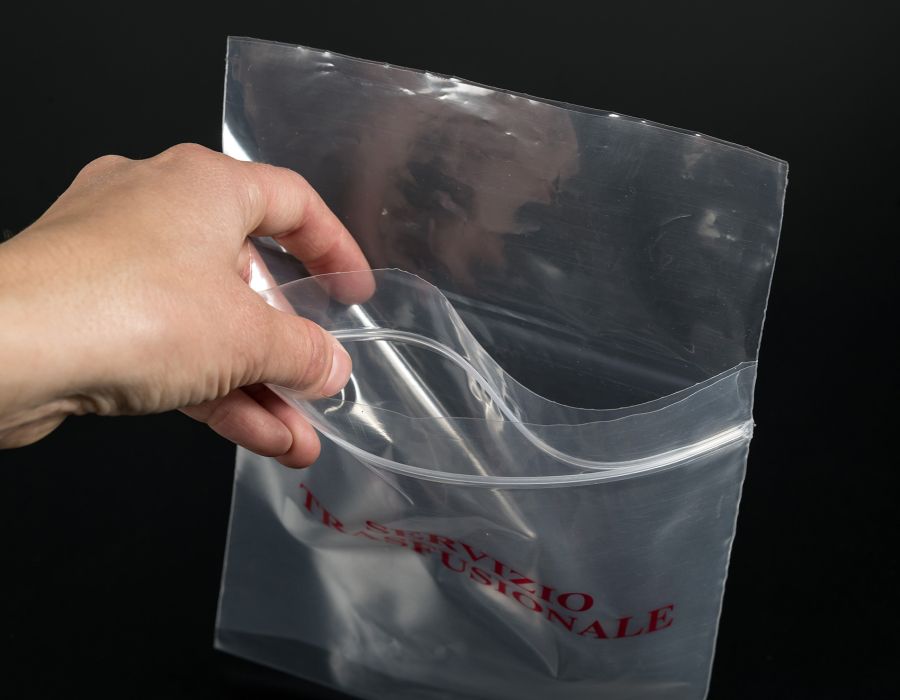

- Flexographic printing up to 6 colors with water-based inks, allowing essential information to be displayed on the packaging such as instructions for use, product properties, identification codes, logos, etc.

- Colored masterbatch, antistatic, and UV stabilizers for delicate and photosensitive products.

- Pre-cuts, holes, and micro-perforations.

- Bags with closure systems: minigrip, maxi zipper, adhesive flap, zip, and other resealable solutions.

- Product traceability.

Certification

Certificates

![]()

EUROPEAN PHARMACOPOEIA

Bags and rolls can be produced using polyethylene compliant with the requirements of the European Pharmacopoeia, specifically monographs 3.1.3 (Polyolefins)

![]()

PARTICLE COUNT CERTIFICATE

Upon request, a particle count analysis certificate can be provided, indicating the level of product contamination, issued by an external specialized laboratory.

![]()

STERILIZATION WITH BETA & GAMMA RAYS

In the case of subsequent sterilization of reels and bags, a color-changing label is applied to the packaging. By observing the change in color of the label, the customer’s laboratory can certify the successful outcome of the sterilization process.

![]()

TRACEABILITY

Each production order can be traced and identified through its batch number.

![]()

CUSTOM PACKAGING

Bags and reels can be packaged in single or double heat-sealed wrapping, depending on the customer’s request.

Excellence of materials and regulatory compliance

Polyethylene is a suitable and highly performing material for packaging intended for the medical and pharmaceutical sectors, where safety, product integrity, and regulatory compliance are essential. Our solutions guarantee total protection of the products, preserve their properties, and prevent any risk of contamination or alteration due to contact with external agents or light.

Each polyethylene package produced for the pharmaceutical and medical sectors is traceable and manufactured in full compliance with current regulations. We can supply polyethylene that meets the specific requirements of the European Pharmacopoeia (monographs 3.1.3 (Polyolefins) and 3.1.4 (Polyethylene without additives for containers for parenteral preparations and for ophthalmic preparations)), ensuring adherence to strict international standards.

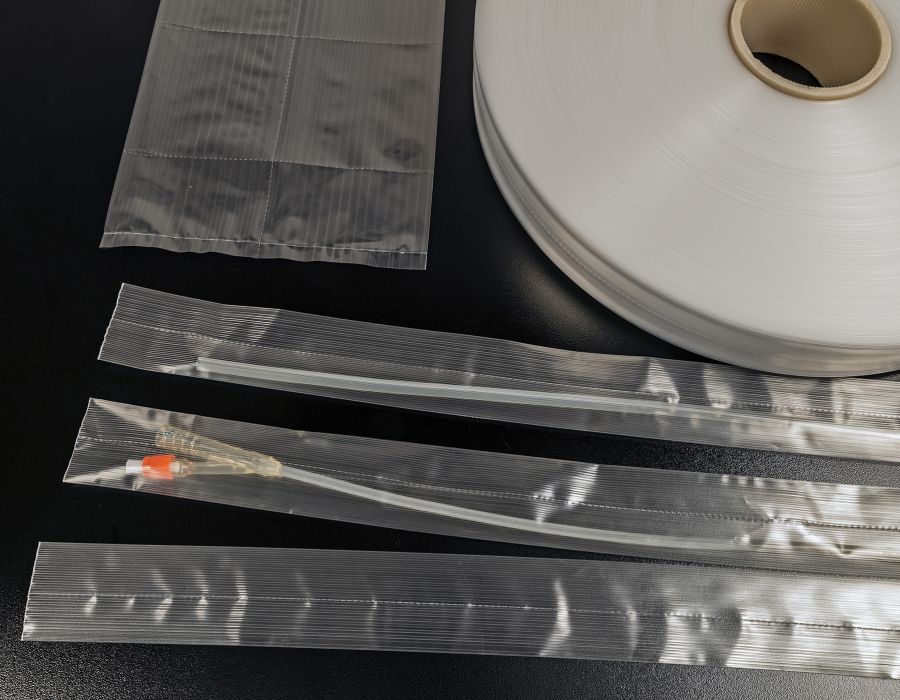

We offer a wide range of polyethylene bags, rolls, pouches, bands, and sheets, customizable in size, finishes, and functionality. Our packaging is suitable for multiple applications, from the packaging of medical devices and active pharmaceutical ingredients to disposable covers for operating rooms and protective bag overwraps.

Our products

Strengths

Guaranteed traceability

A distinctive feature of Priula is the guaranteed traceability of each production order through its batch number, allowing accurate control and efficient management.

Production flexibility

The company can also meet requests for small-batch productions, demonstrating flexibility and attention to customers’ specific needs.

Customized packaging

Bags and rolls can be packed in single or multiple heat-sealed packaging, according to customer requirements.

Environmental responsibility

All production waste is professionally recovered and recycled. In the printing process, only eco-friendly, water-based inks are used.

Quality policy

Quality and cost both contribute to customer satisfaction, a necessary condition for the success of our company.