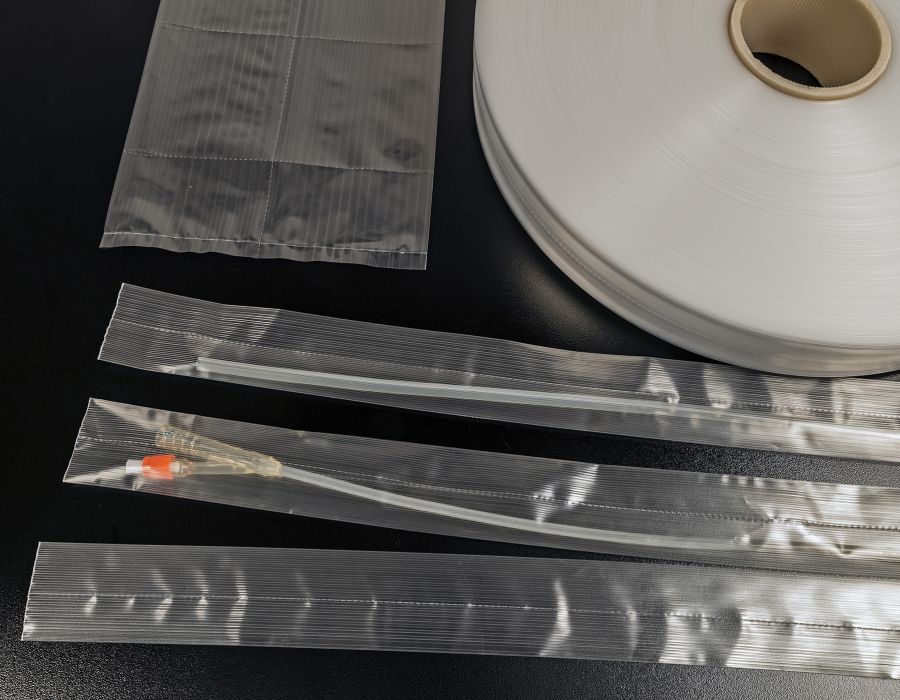

Medical bags, bands and wrapping sheets

Polyethylene bags, bands, and sheets are used in the pharma-medical sector as secondary packaging for the storage and transport of medical and pharmaceutical products, such as active pharmaceutical ingredients (API bags) and bulk materials.

They are made of HDPE, LDPE, and Purell polymer, materials that meet the strict safety, mechanical, and chemical resistance standards required by the industry to ensure content integrity and tamper-resistance during transport.

Medical Grade bags (medical paper), made of paper laminated with PE film, are highly resistant and act as a protective barrier against microbial contamination of sterilized products.

Our bags are available in various thicknesses and sizes and can be supplied sterile and cytotoxicity tested, ensuring the non-toxicity of the material.

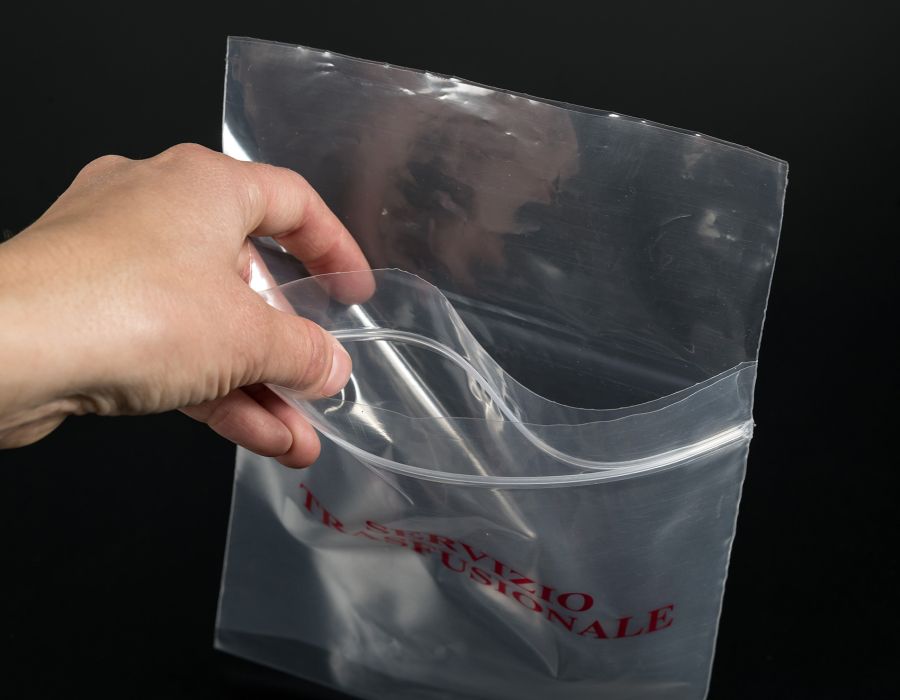

For specific requirements, customizable solutions are available with printing of instructions, logos, or tracking codes, essential for proper identification of transported materials.

- Medical bags / Medical sacks

- Pharmaceutical polyethylene bags / Medical polyethylene bags

- Purell bags / Purell sacks

- Medical Grade bags

- Pharmacopoeia-compliant polyethylene bags

- Cytotoxicity-tested medical bags

- Medical polymer bags / Purell polymer bags

- Certified polyethylene bags

- Sterilized polyethylene bags

- Polyethylene bags / Polyethylene pouches

- PE bags / PE pouches / Plastic bags

- Medical Cartene bags / Cartene pouches

- Printing: neutral product or flexographic printing up to 6 colors

- Masterbatch: colored, antistatic, and/or UV resistant upon request

- Pre-cuts, holes, and micro-perforations available upon request

Certificates

![]()

EUROPEAN PHARMACOPOEIA

Bags and rolls can be produced using polyethylene compliant with the requirements of the European Pharmacopoeia, specifically monographs 3.1.3 (Polyolefins)

![]()

PARTICLE COUNT CERTIFICATE

Upon request, a particle count analysis certificate can be provided, indicating the level of product contamination, issued by an external specialized laboratory.

![]()

STERILIZATION WITH BETA & GAMMA RAYS

In the case of subsequent sterilization of reels and bags, a color-changing label is applied to the packaging. By observing the change in color of the label, the customer’s laboratory can certify the successful outcome of the sterilization process.

![]()

TRACEABILITY

Each production order can be traced and identified through its batch number.

![]()

CUSTOM PACKAGING

Bags and reels can be packaged in single or double heat-sealed wrapping, depending on the customer’s request.