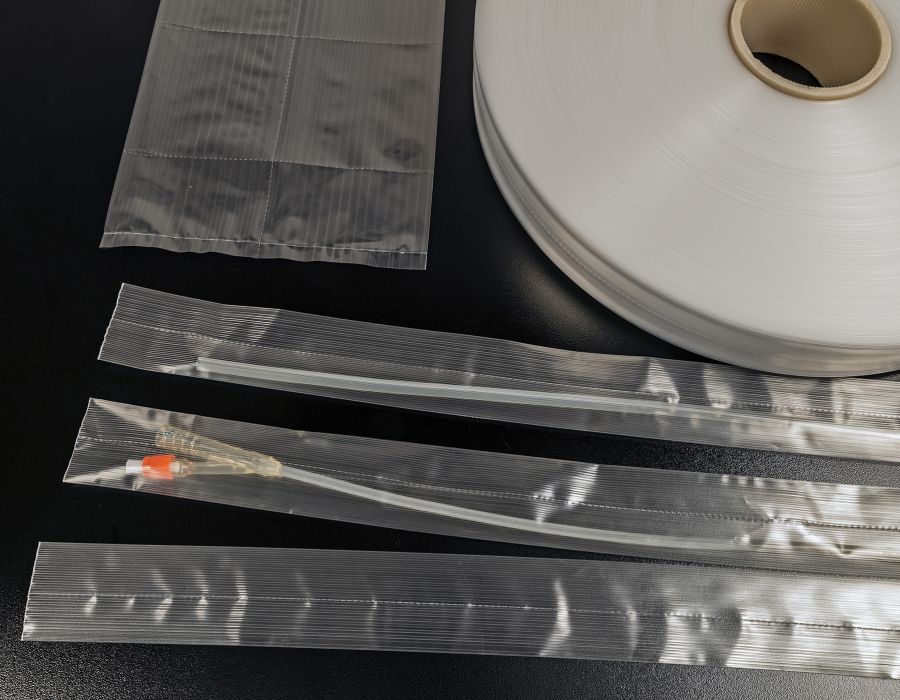

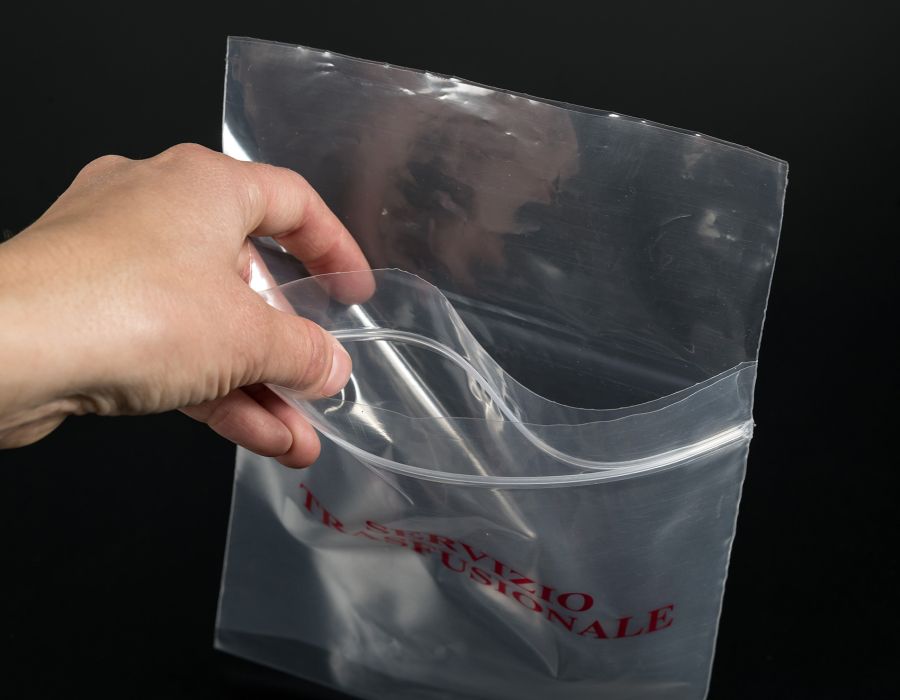

Bags for infusion and transfusion sets

Polyethylene bags, made of LDPE and HDPE, are designed for the safe packaging of infusion and transfusion sets. Product integrity is ensured throughout all stages of transport and storage, up to the opening of the bag.

These bags can be sterilized with ethylene oxide, in compliance with health and safety requirements for medical use.

Polyethylene bags can be manufactured with pre-cuts and easy-opening systems, simplifying their use and operations in hospitals. Printing options include instructions for use, technical specifications, and other customer-requested information for clear and traceable product management.

- V infusion set bags

- IV set bags

- Printing: transparent bags or flexographic printing up to 6 colors

- Pre-cuts and easy-opening solutions

- Closure systems: minigrip, maxi zipper, adhesive flap, zip, and other resealable solutions

- Colored, antistatic, and/or UV-resistant masterbatch upon request

- Holes and micro-perforations upon request

Certificates

![]()

EUROPEAN PHARMACOPOEIA

Bags and rolls can be produced using polyethylene compliant with the requirements of the European Pharmacopoeia, specifically monographs 3.1.3 (Polyolefins)

![]()

PARTICLE COUNT CERTIFICATE

Upon request, a particle count analysis certificate can be provided, indicating the level of product contamination, issued by an external specialized laboratory.

![]()

STERILIZATION WITH BETA & GAMMA RAYS

In the case of subsequent sterilization of reels and bags, a color-changing label is applied to the packaging. By observing the change in color of the label, the customer’s laboratory can certify the successful outcome of the sterilization process.

![]()

TRACEABILITY

Each production order can be traced and identified through its batch number.

![]()

CUSTOM PACKAGING

Bags and reels can be packaged in single or double heat-sealed wrapping, depending on the customer’s request.