Anti-UV photoprotective bags

UV-protective polyethylene bags are produced with light-blocking coloring and specific additives to shield ultraviolet rays. This finish makes them particularly suitable as protective packaging and covers for photosensitive substances and devices, preserving their stability and integrity. The anti-UV action prevents possible alterations caused by exposure to sunlight.

In addition to photo-shielding protection, these bags maintain all the properties of polyethylene, such as resistance to tearing, mechanical stress, and external agents.

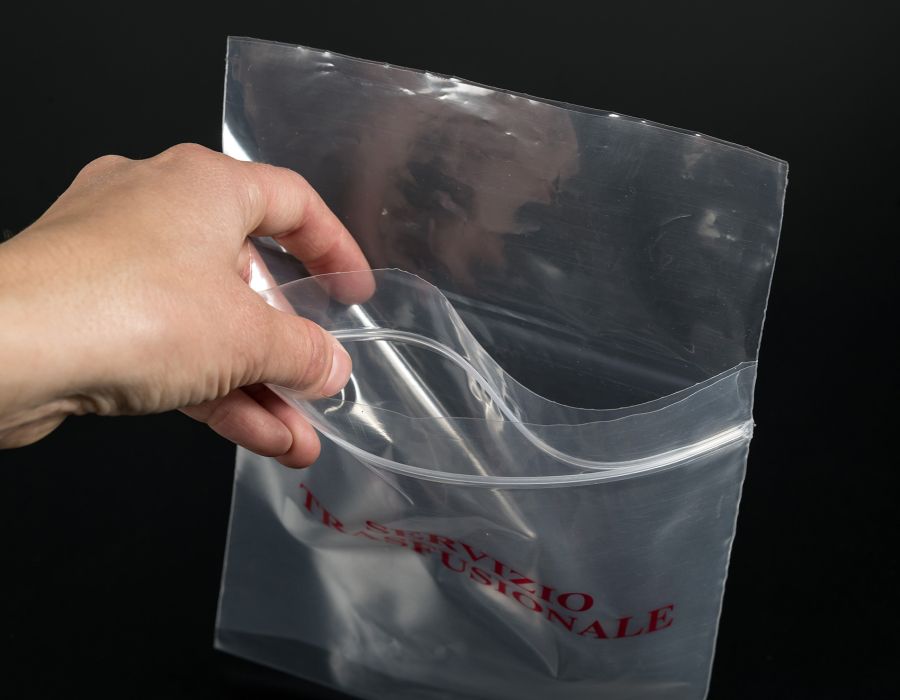

For these reasons, they are widely used in the medical sector, particularly as covers for nutritional bags, photosensitive drugs, and healthcare devices.

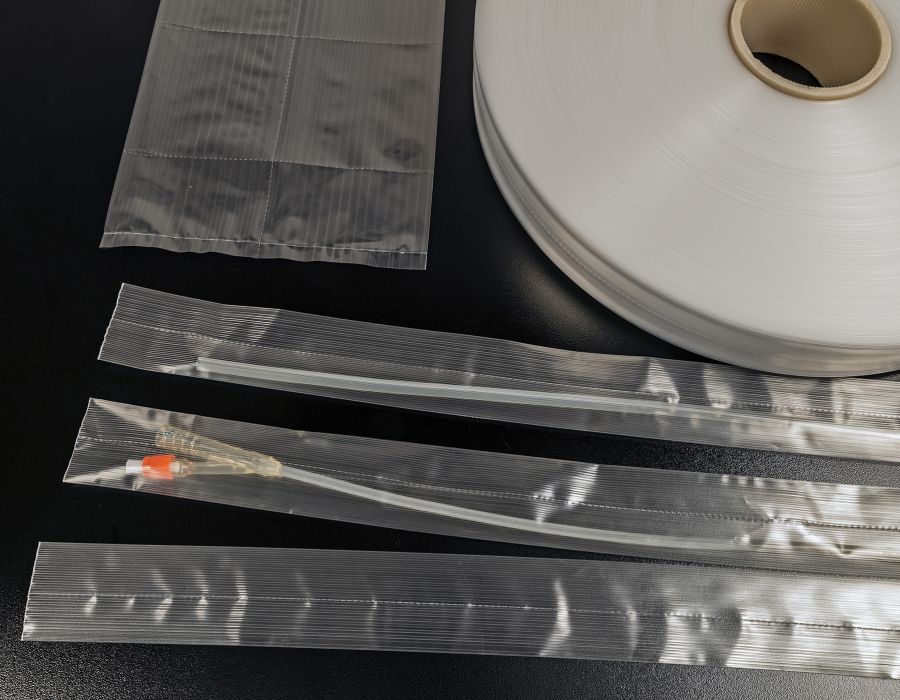

Upon request, UV-protective polyethylene bags can be printed with information such as instructions for use, warnings about the content, and disposal guidelines. They can also be produced with specific opening/closure systems and/or holes for hanging on supports or for tube outlets.

- UV barrier photo-protective bags / UV ray protective bags

- Bags for photosensitive substances / covers for photosensitive substances

- Medical bag covers

- Nutritional bag covers

- Light-blocking medical bags

- Photo-shielding gowns

- Printing: transparent bags or flexographic printing up to 6 colors

- Colored masterbatch available upon request

- Easy-opening systems

- Closure systems: adhesive flap, press-to-close zipper, zip closure

- Pre-cuts, holes, and micro-perforations upon request

Certificates

![]()

EUROPEAN PHARMACOPOEIA

Bags and rolls can be produced using polyethylene compliant with the requirements of the European Pharmacopoeia, specifically monographs 3.1.3 (Polyolefins)

![]()

PARTICLE COUNT CERTIFICATE

Upon request, a particle count analysis certificate can be provided, indicating the level of product contamination, issued by an external specialized laboratory.

![]()

STERILIZATION WITH BETA & GAMMA RAYS

In the case of subsequent sterilization of reels and bags, a color-changing label is applied to the packaging. By observing the change in color of the label, the customer’s laboratory can certify the successful outcome of the sterilization process.

![]()

TRACEABILITY

Each production order can be traced and identified through its batch number.

![]()

CUSTOM PACKAGING

Bags and reels can be packaged in single or double heat-sealed wrapping, depending on the customer’s request.